Keeping the suppy chain working with 6S Sanitize - Social Distancing - Wearing Masks

Committed to Quality Vibrators, Fastest Shipping, Exceptional Service

Living Lean “Shaking the waste”

One result of Living Lean is having Set Up Times dramatically reduced (73% in 6 months) resulting in smaller batches, increased capacity, improved delivery times, and fewer defects. Shadow Boards are used to keep necessary tools organized with identical tool setups for each station. This allows machinists to work efficiently at any machine. This kind of system thinking increases the velocity of production. White Boards communicate what jobs are running. Using Teamwork, our machinists (and our office) stage materials and tools, and share set up standardized steps to minimize downtime.

Using Cellular Manufacturing, our Big Bertha™ assembly capacity increased by 500% after a four day Kaizen event. Using In-Cell Testing (quality at the source) any quality issues are identified immediately by assembling one complete unit at a time (one piece flow). Our Weld Shop Through-Put survived a difficult staffing situation, without losing momentum on a rapidly growing product line. Using highly skilled, multi-tasked employees we created flexibility through cross training.

In our office, we streamlined processes across the board with Six Sigma Training by looking at inventory, IT systems and demands on key personnel. Multiple PC Monitors were introduced at all workstations, resulting in a 50% productivity increase. Necessary information is always available for staff to multi-task more efficiently. President, Karl Wadensten expresses this concept as: “One click, one breath, one motion, one second, one team.”

We are a strengths based organization maximizing on everyones unique characteristics. All new employees complete an assessment using Clifton’s Strengths Finder so the team can incorporate their own strengths and make the most of individual talents. And Karl, our CEO is a Strengths Coach who helps employees realize their natural tendencies to excel in their positions.

2019 Vibco crew (with our favorite canines) showing our employee's 5 highest Clifton Strengths.

One of VIBCO’s strengths is our Wealth of Engineering Expertise. VIBCO sponsors Engineering Capstone projects with many Universities throughout New England. This brings in the best and brightest students each year as interns; both in the engineering group and in our offices. 10% of our workforce is comprised of millennial and interns, giving us unique perspectives for coaching, mentoring, and co-learning together.

VIBCO as a lean partner - “make the impossible possible”

VIBCO listens to dealers and views them as strategic partners. This opens the door for opportunities to increase on time delivery by offering stocking programs (Kanban) that will meet their needs. On time delivery means getting the product in their customer’s hands when the customer requires it. VIBCO offers our strategic partners (our dealers, OEMs, and distributors) expert training and technical assistance to get it right the first time for their customers.

We strive to keep all units in our “grocery store” for easy availability to ship which are always in stock. We have met this goal with standard units and will continue to improve until every VIBCO product (except custom) will ship the same day of purchase.

VIBCO is working to improve lead times for custom items, by reducing the time it takes to design, quote, and build. Using DFMA (Design for Manufacture and Assembly) and the reduction of Waste (Muda), has kept us competitive in the market. Employees are encouraged to think about how to work more efficiently by using lean processes. Vendor or supplier partnerships that result in improved quality, reduced costs, innovations, and on-time delivery are sought out.

Embracing Fish Philosophy and a "Happy to Do It" culture has made our lean journey much more fun and sustainable by inspiring passion! A real person answers our phones. NO VOICE MAIL or AUTOMATION MESSAGES! We’re the Expert Vibrator Guys! and each day we try to “be” and “live” that by listening to each other and to our customers – one customer at a time. We don’t want to be good; we want to be great! This means taking care of every customer efficiently, expertly, with a “can-do; will-do” spirit. We stay on time, tuned in, and engaged in our work we do every day. Ideas and innovation from ALL employees are valued and considered.

The Original “Fix What Bugs You™”

Our culture for continuous improvement is as natural as breathing. It is something we do intuitively every minute of every day: listening and reacting to the voice of the customer and fixing what bugs us!

We understand that you make your purchasing decisions based on value and cost. We create value by manufacturing high-quality, low maintenance industrial vibrators, construction vibrators and other vibratory equipment; offering world-class vibrator technical support and personalized service; and innovating to ensure that you have access to the best possible vibration solutions. The whole VIBCO team is committed to our  VIBCO Vibrators True North — Quality, Throughput, Innovation and Same Day, Next Day.

VIBCO Vibrators True North — Quality, Throughput, Innovation and Same Day, Next Day.

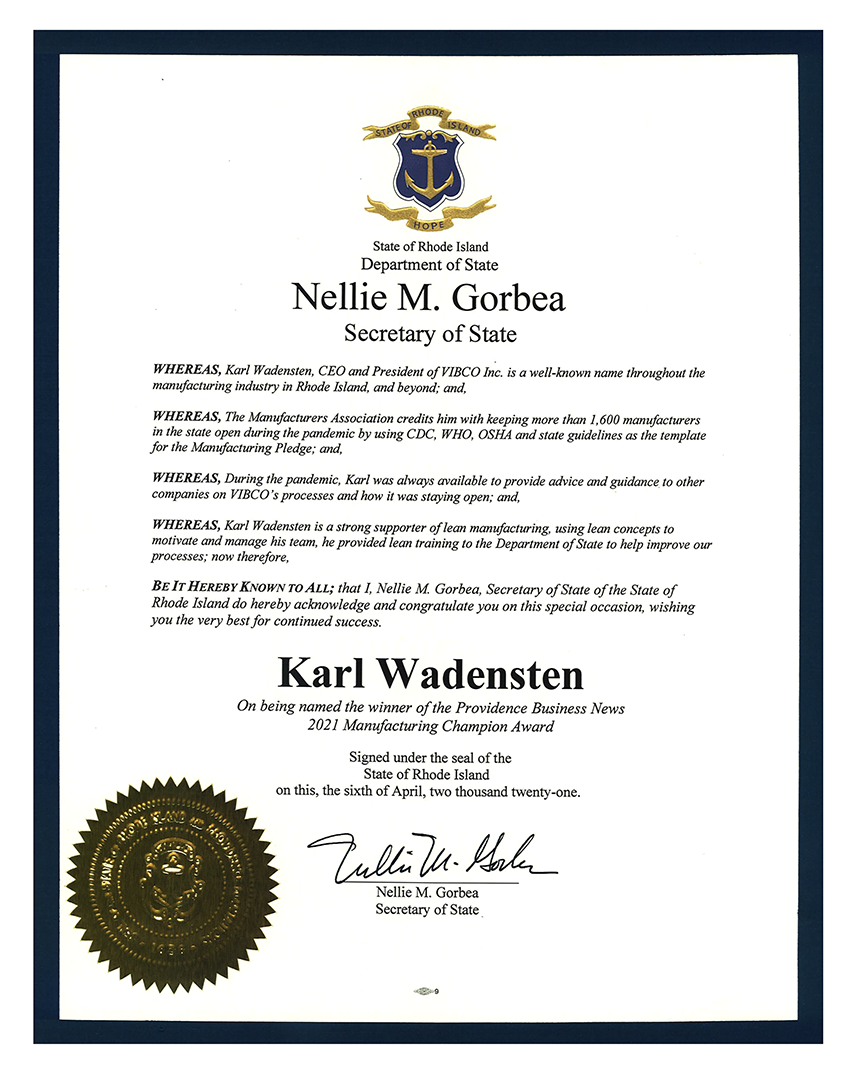

We're Proud of Our Awards

We are so proud of our awards because they are a reflection of our commitment to you and our relentless pursuit of perfection.

• 2021 PBN's Manufacturing Champion, Karl Wadensten

2021 Get Started Rhode Island Panelist, COX Communications,

• 2020 PBN's 25 Leaders and Achievers, Karl Wadensten

2020 Get Started Rhode Island Panelist, COX Communications,

• 2019 PBN Manufacturing Award for, Workforce Development & Productivity

2019 Get Started Rhode Island Panelist, COX Communications,

• 2018 Gallup’s CEO, Jim Clifton, Names VIBCO

“Ground Zero for Organizations learning Strengths.”

2018 Get Started Rhode Island Panelist, COX Communications,

• 2017 PBN Manufacturing Award for, Excellence in LEan Manufacturing

• 2017 AME, Journey to Excellence

• 2016 URI, CEO Karl Wadensten, Earns Lean Six Sigma Black Belt

• 2015 Recognized by Gov. Gina Raimondo for hosting Lean Government Initiative

• 2009 Managing Automation’s Progressive Manufacturing 100

• 2009 PBN Manufacturing Award for, Best Places to Work

• 2009 Silver Toaster Award, Employee Excellence in Lean

• 2008 RIMA Award, Commitment to Manufacturing

• 2008 Governor’s Workforce Innovation Award

• 2008 Diversity Business, Top 100 Privately Held Business in RI

• 2007 PBN Manufacturing Award for, Business Excellence Award

• 1996 Service Award, Cooperative Education and School-to-Work Opportunities